In today's industrial production field, lime is an important basic raw material, and the performance and quality of its production equipment directly affect the quality of products and the efficiency of enterprises. Double chamber lime kiln, as an efficient and energy-saving lime production equipment, has been favored by many enterprises. Jinyong Kiln, with its professional technical team and rich industry experience, provides customers with non-standard customized services for the complete set of double chamber lime kiln equipment, meeting their personalized needs and helping enterprises stand out in the fierce market competition.

1、 The advantages and applications of double chamber lime kiln

The double chamber lime kiln has many significant advantages, making it an ideal choice for lime production.

Firstly, it has high thermal efficiency. Through the unique dual chamber structure design, efficient utilization of heat has been achieved, greatly reducing energy consumption and saving production costs for enterprises. Secondly, it has strong production capacity. Capable of continuously and stably producing high-quality lime to meet the needs of large-scale industrial production.

Furthermore, the product quality is stable. Accurate temperature control and uniform calcination process ensure the consistency of lime quality, meeting various strict industrial standards. Double chamber lime kilns are widely used in various fields such as steel, metallurgy, chemical engineering, and environmental protection. In the steel industry, it is used for slagging and desulfurization in the steelmaking process; In the metallurgical industry, providing high-quality fluxes for metal extraction and refining; In the chemical industry, it is an important raw material for the production of chemical products such as calcium carbide and soda ash; In terms of environmental protection, it can be used to treat industrial waste gas and wastewater.

2、 Characteristics of customized non-standard equipment services for Jinyong Kiln

Jinyong Kiln is well aware that each customer's production needs and process conditions are not the same, so it is committed to providing personalized customized services for non-standard equipment of double chamber lime kilns. In depth requirement analysis

Before the project begins, the professional team of Jinyong Kiln will have in-depth communication with the client to comprehensively understand their production scale, raw material characteristics, product requirements, site conditions, and other factors. Through detailed research and analysis, develop the most suitable equipment solution for customers.

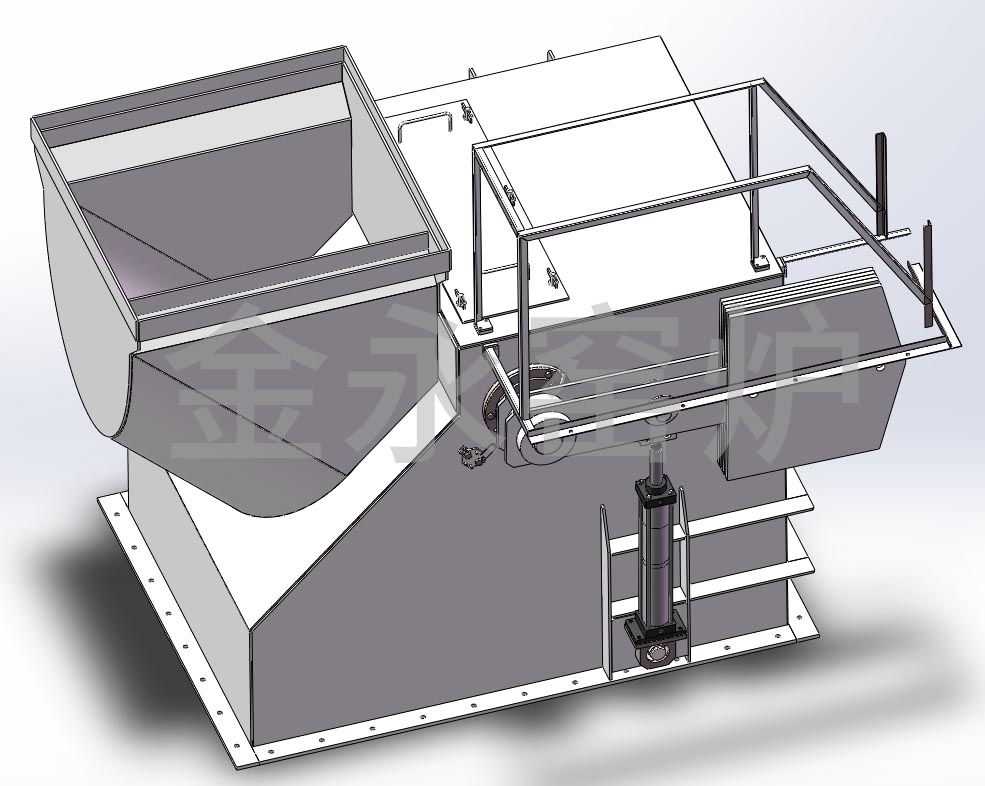

Exquisite design and research and development

Jinyong Kiln has an experienced and skilled design and development team. They use advanced design software and simulation technology to accurately model and simulate the double chamber lime kiln. In the design process, full consideration is given to the structural strength, thermal performance, ease of operation, and maintainability of the equipment to ensure its reliability and stability. Taking a double chamber lime kiln project operating in a high-temperature environment as an example, the design team of Jinyong Kiln effectively reduced the surface temperature of the kiln body and extended the service life of the equipment by optimizing the insulation structure and cooling system of the kiln body, while improving the safety of the operators' work.

Strict quality control

Quality is the lifeline of Jinyong Kiln. In the process of equipment manufacturing, from raw material procurement to component processing, to equipment assembly and debugging, every link is strictly controlled in accordance with international standards and quality systems. By using advanced testing equipment and methods, strict inspection and testing of key components are carried out to ensure that the quality of the equipment meets or exceeds customer expectations.

For example, in the selection of refractory materials, Jinyong Kiln only uses high-quality refractory bricks and castables, and conducts strict fire resistance performance tests to ensure the long-term stable operation of the kiln in high temperature environments.

Comprehensive after-sales service

Jinyong Kiln not only focuses on equipment sales, but also pays attention to the long-term user experience of customers. Provide comprehensive after-sales service, including equipment installation guidance, debugging training, operation and maintenance consulting, and spare parts supply. During the operation of the equipment, regularly follow up with customers to promptly solve any problems they encounter and ensure that the equipment always maintains a good operating condition.

Once a customer experienced a decrease in production after running the equipment for a period of time. The after-sales service team of Jinyong Kiln quickly responded and after on-site investigation and analysis, it was found that it was caused by some spray guns being blocked. The after-sales personnel promptly cleaned the spray gun and provided training to the customer's operators to prevent similar problems from happening again. Jinyong Kiln will continue to increase investment in technological innovation and research and development, continuously improving the level of customized services for non-standard equipment of double chamber lime kilns.

Introduce advanced technologies such as artificial intelligence and big data to achieve intelligent operation and remote monitoring of equipment. By real-time collection and analysis of equipment operation data, equipment failures can be predicted in advance, and maintenance and upkeep can be carried out in a timely manner to improve the efficiency and stability of equipment operation. Strengthen cooperation with domestic and foreign research institutions and universities, and jointly carry out cutting-edge technology research and new product development. Continuously introducing more energy-efficient, environmentally friendly, and efficient double chamber lime kiln equipment to create greater value for customers.

As an industry leader in customized services for non-standard equipment of double chamber lime kilns, Jinyong Kiln will always adhere to the business philosophy of "customer-centric, survival through quality, and development through innovation", and provide customers with the highest quality products and services. Choosing Jinyong Kiln is choosing professionalism, quality, and success!