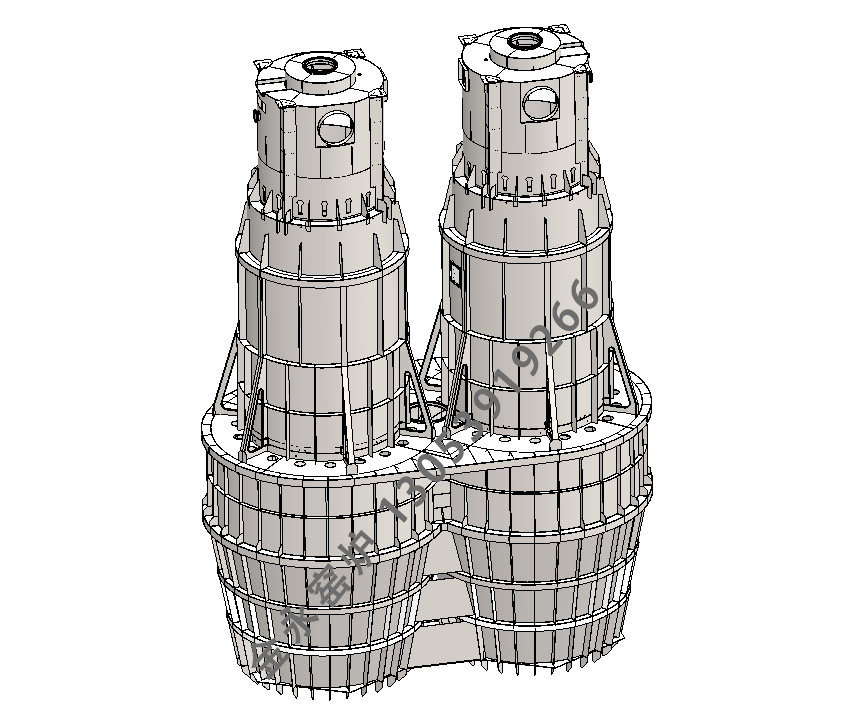

It is a fact that many people have already known that the activity of lime calcined in a double chamber lime kiln is high. In the modern lime kiln industry, the development speed is fast, and many technologies emerge endlessly. The new double chamber lime kiln built by Jinyong Kiln Co., Ltd. adopts a double chamber structure design, which has a high activity of calcining lime and is suitable for various smelting industries or construction industries.

The dual chamber lime kiln adopts the advanced concurrent flow thermal storage calcination principle. The combustion supporting air, fuel, and materials all flow downward from the upper part of the calcination belt, with the same flow direction. The materials achieve gradient combustion, thereby avoiding over burning. At the same time, the material in the cooling belt and the cooling air are converging in the opposite direction, allowing the material to quickly cool, thereby improving the activity of the lime.

Due to the conditions for the formation of limestone and combustion gas in the combustion kiln barrel, this lime kiln type is very ideal for producing light burned lime, high activity lime, and dolomite lime. In addition, the heat storage process minimizes the heat loss of this lime kiln type among all current lime kiln types. Figure 1 shows the difference between a traditional single cylinder lime kiln and a parallel flow regenerative lime kiln in the temperature curve. The curve shows the temperature of raw materials, air, and combustion gas flowing through the lime kiln.

The single cylinder lime kiln usually adopts counter flow combustion, and its temperature curve is shown. The green line represents raw materials, the blue line represents cooling air, and the red line represents combustion and exhaust gases. Since the amount of cooling air is not sufficient to complete the complete combustion of the fuel, additional air must be added through the side burner. The fuel for this type of lime kiln enters here from the lower end of the calcination belt. The raw materials have been calcined, and the temperature in this area is significantly higher than the temperature required to produce highly active lime.

Therefore, the activity of lime calcined in a double chamber lime kiln exceeds 300 or more, with a high activity, and is used in many industries.